INSTRUMENTATION & SENSORS

We provide complete instrumentation and sensor solutions for industrial plants, focusing on accuracy, reliability, and seamless integration with PLC, SCADA, and AI-based monitoring systems.

Our instrumentation systems are designed to deliver real-time data for control, optimization, and predictive maintenance.

Instrumentation Systems We Handle

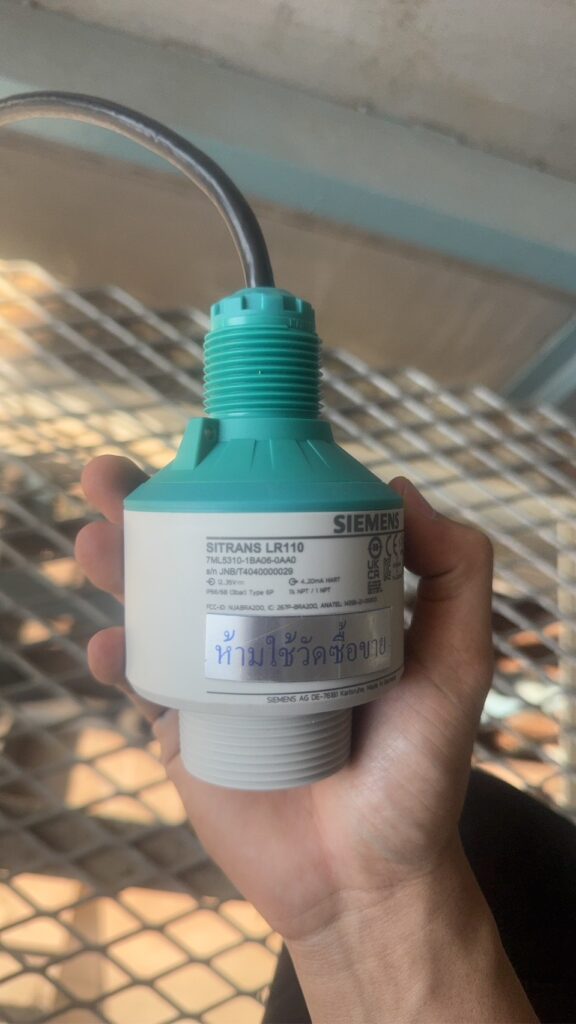

Level Measurement

Pressure & Differential Pressure

Pressure Transmitter

Differential Pressure (DP) Transmitter

Filter & Pump Monitoring

Flow calculation using DP

Supports process control and equipment protection.

Our long-term experience in industrial automation allows us to design, integrate, and maintain PLC, SCADA, and instrumentation systems that operate reliably in real production environments.

We understand not only how systems work, but how they behave over time under actual plant conditions.

Our engineering team consists of experienced automation, electrical, and instrumentation engineers who specialize in:

PLC programming and system architecture

SCADA design, visualization, and data management

Instrumentation selection and signal integrity

Industrial networking and communication protocols

We focus on practical, stable solutions that are easy to maintain and expand in the future.

We provide full-cycle technical support covering:

System design & engineering

Installation & commissioning

Troubleshooting & optimization

Long-term maintenance and upgrades

Our service philosophy is to ensure system stability, minimize downtime, and support continuous plant operation.

- Industrial-grade accuracy

- Reliable long-term operation

- Seamless PLC & SCADA integration

- Ready for AI & digital factory systems

- Experience with real production environments

Why Choose Our Instrumentation Solutions

We follow industrial best practices for installation:

Proper sensor mounting & orientation

Shielded signal wiring & grounding

Noise and interference protection

Loop checking & calibration

FAT / SAT documentation

Ensuring long-term stability and measurement accuracy.