About the project

- Date: August 20, 2018

- Client: Envato Group, US

- Category: Solar

- Address: 2946 Angus Road, NY

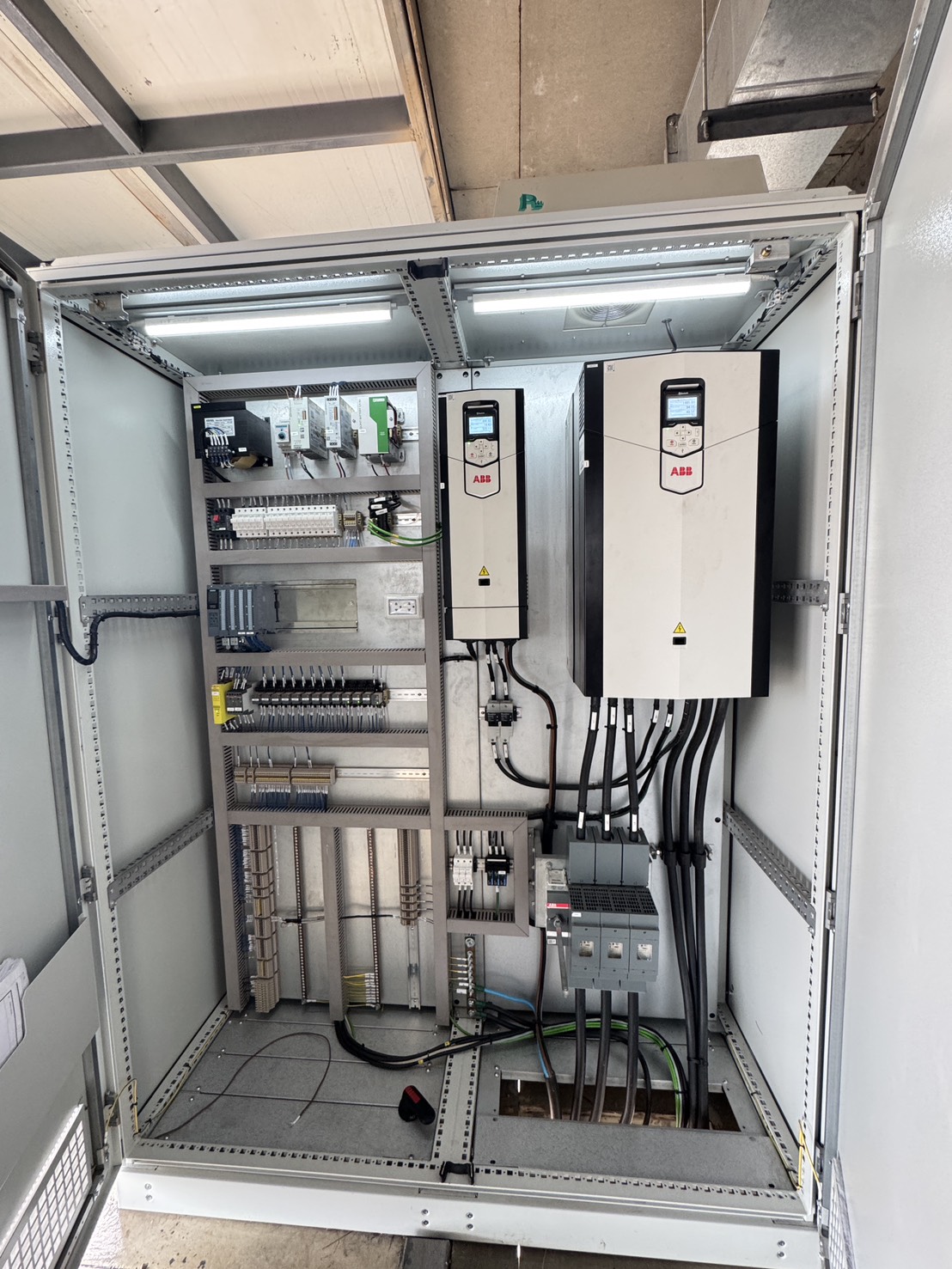

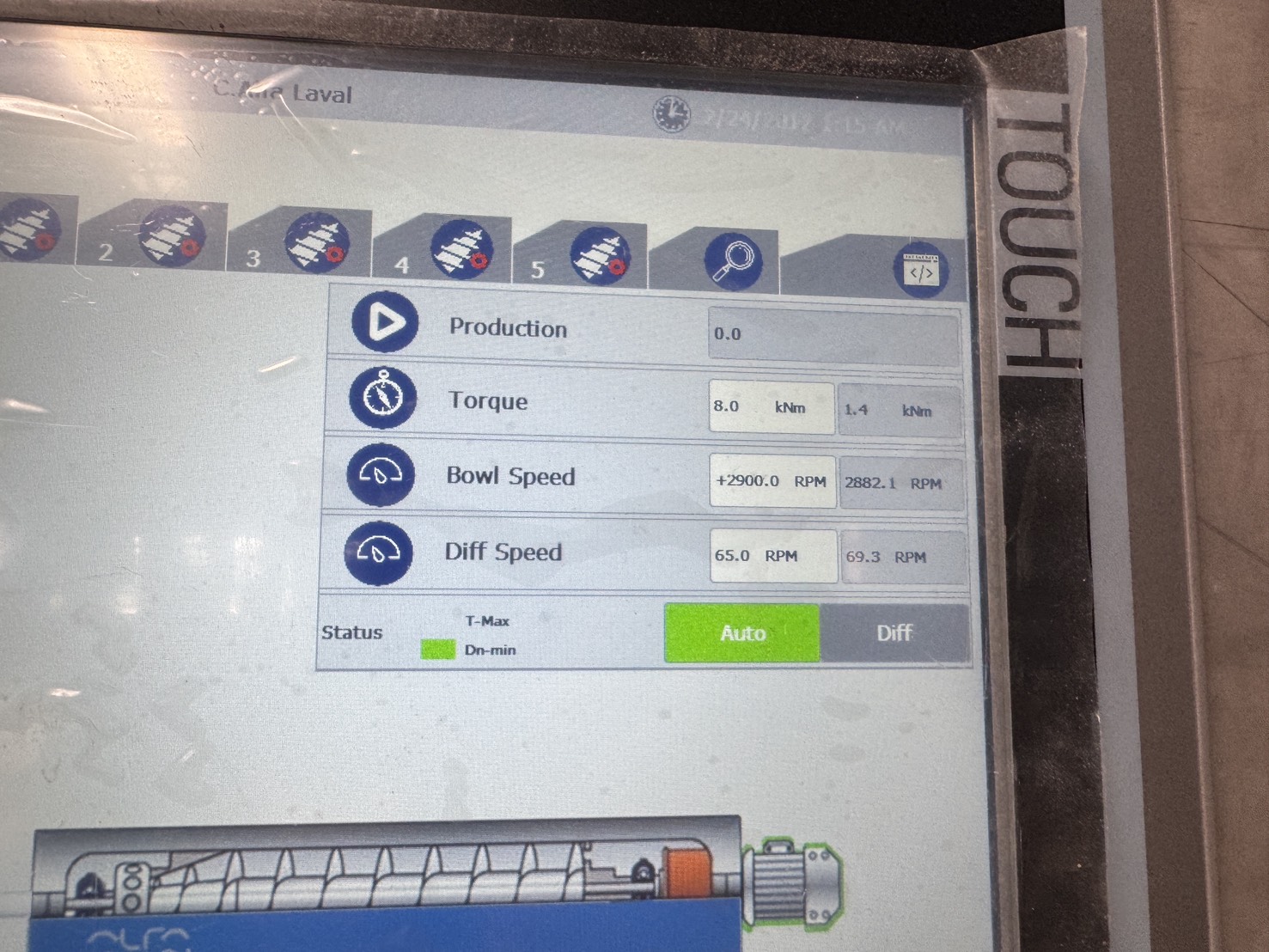

The Automatic Control Decanter Machines Project was developed to modernize and fully automate the decanter process within an industrial production plant. The objective of this project was to upgrade conventional control methods into a centralized, intelligent PLC and SCADA-based automation system, ensuring stable operation, high efficiency, and long-term reliability.

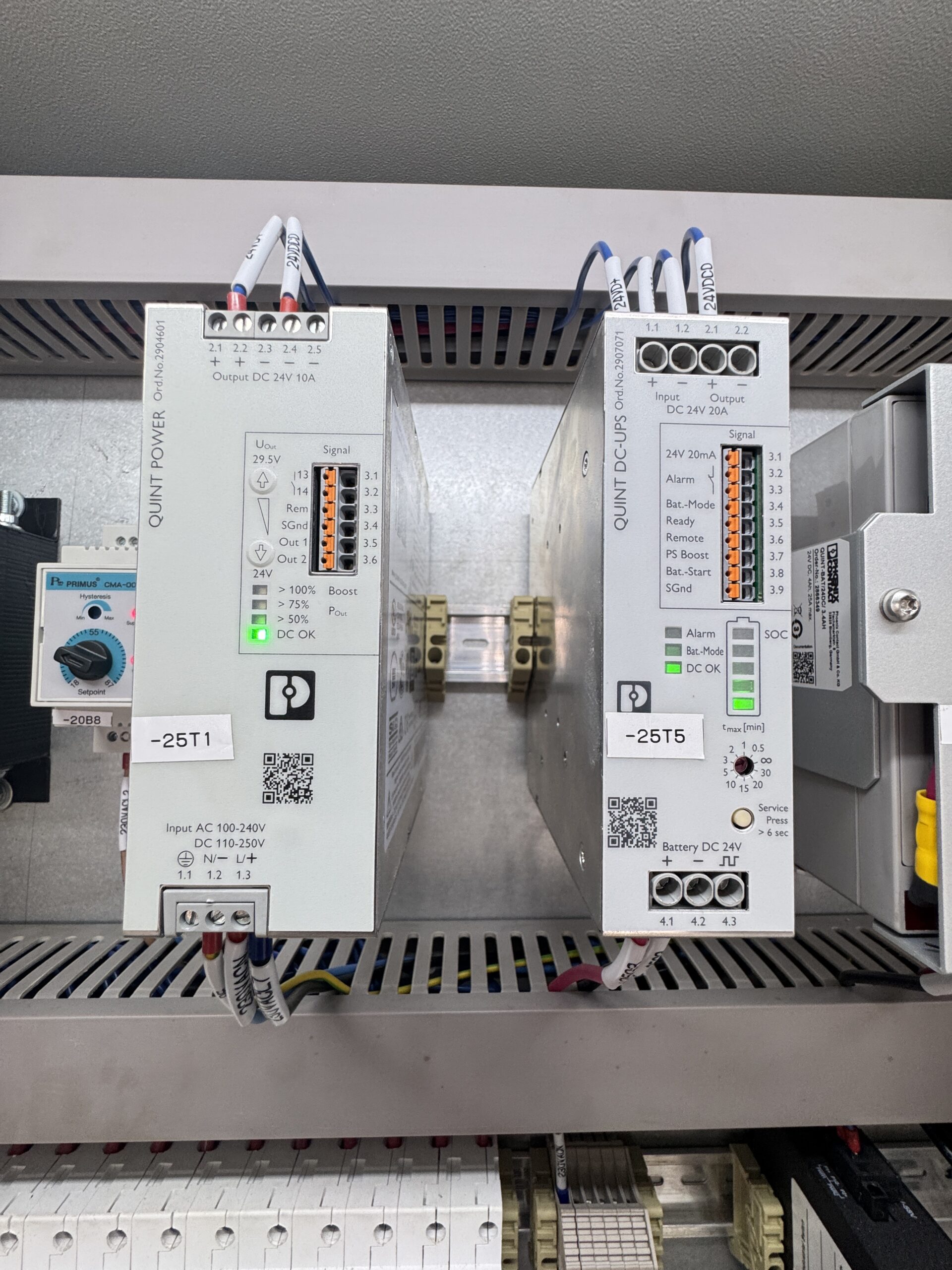

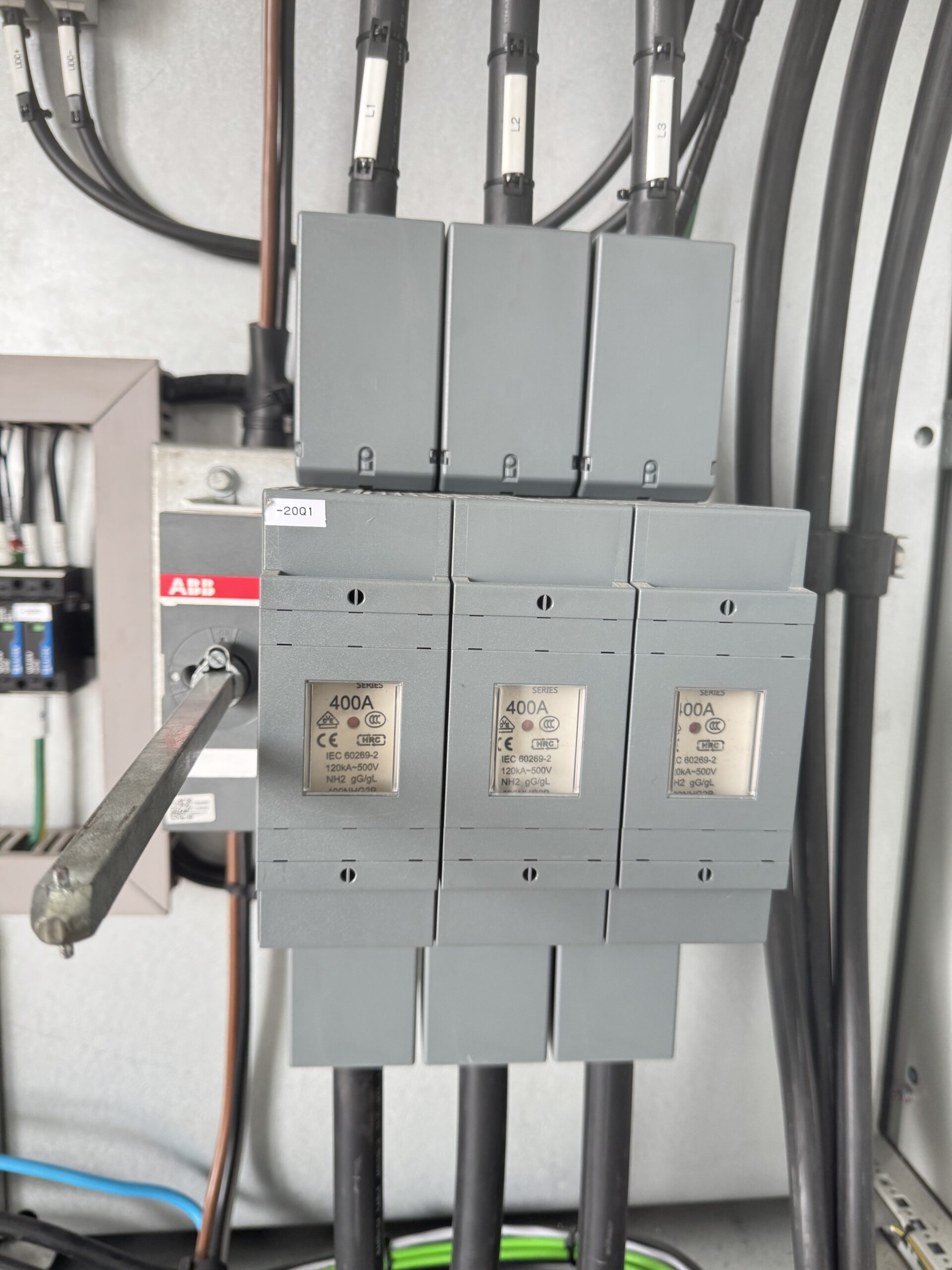

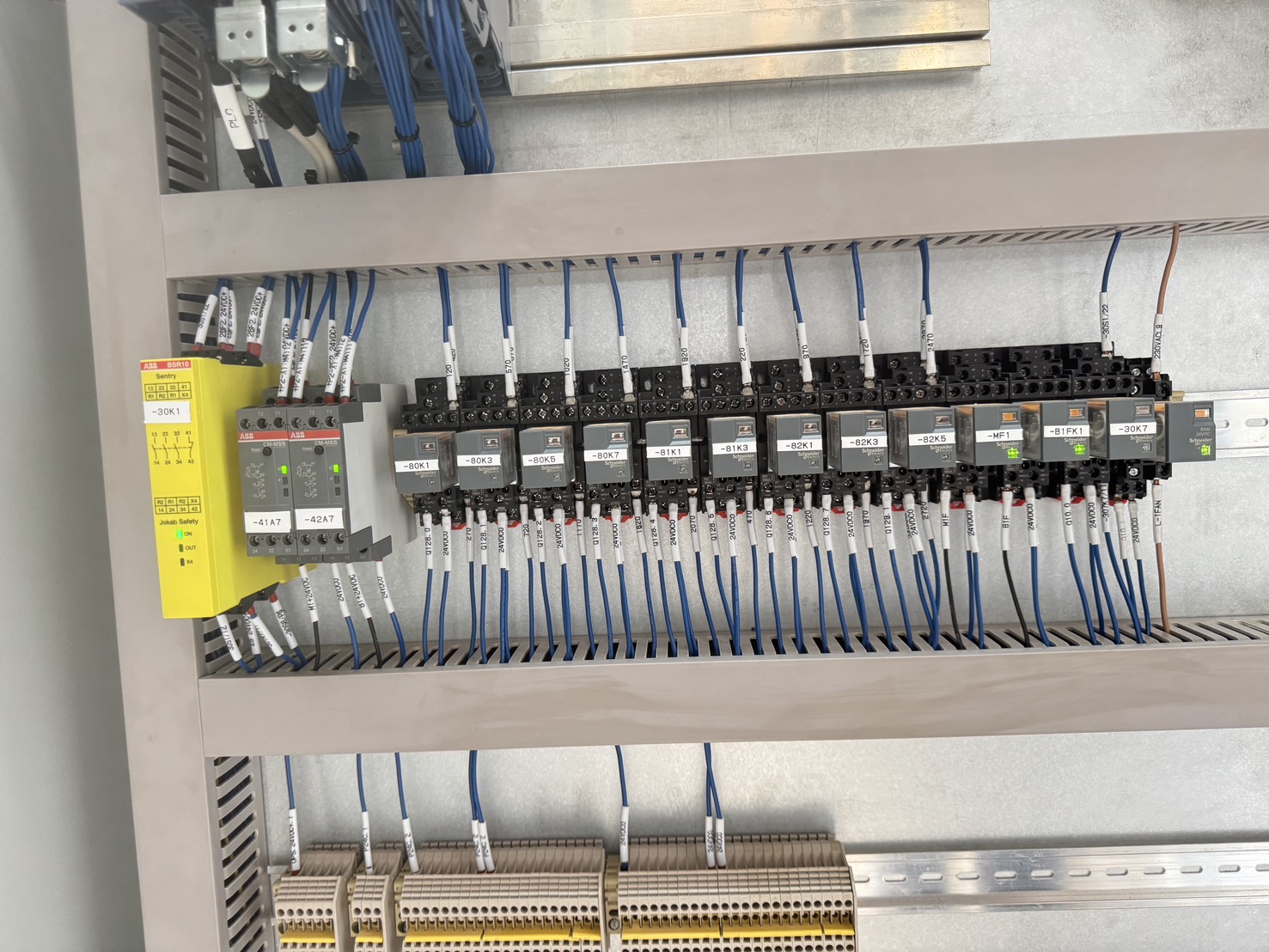

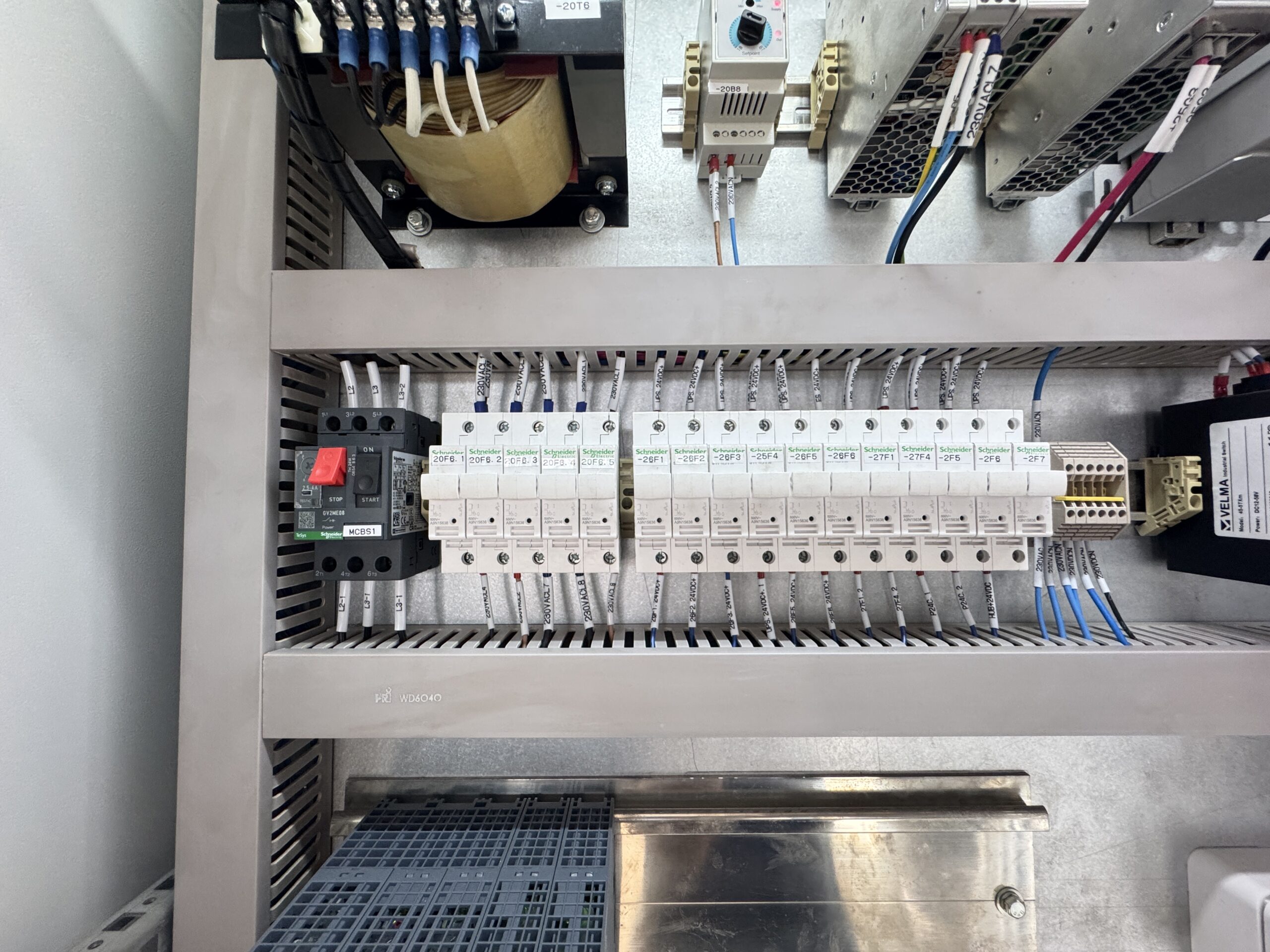

Our scope of work covered the complete control system lifecycle, including electrical panel design, power distribution, PLC programming, instrumentation integration, and SCADA implementation. Variable Frequency Drives (VFDs) were applied to precisely control motor speed and torque, allowing the decanter to operate optimally under varying load and process conditions.

All critical process parameters—such as rotational speed, vibration, current, torque, temperature, and process flow—are continuously monitored in real time. The SCADA system provides operators with a clear visualization of machine status, alarms, trends, and historical data, enabling fast decision-making and preventive maintenance.

Advanced automation logic was implemented to manage startup sequences, interlocks, fault handling, and safe shutdown procedures. This ensures maximum equipment protection, reduced downtime, and improved operational safety. The system is also designed to integrate seamlessly with upstream and downstream processes, supporting plant-wide automation and centralized control.

This project reflects a complete industrial automation solution, transforming traditional decanter machines into a fully automated, high-performance production system.