Benefits of Project

Reliable and stable electrical control for process plant operation

Improved operational safety and equipment protection

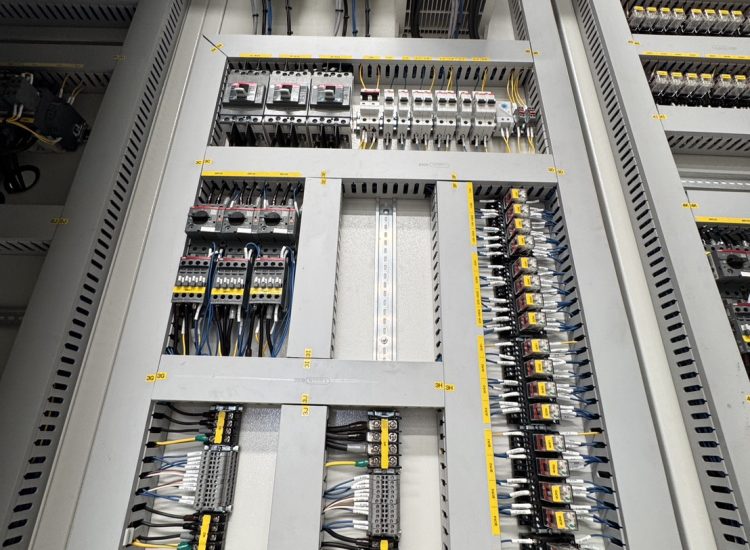

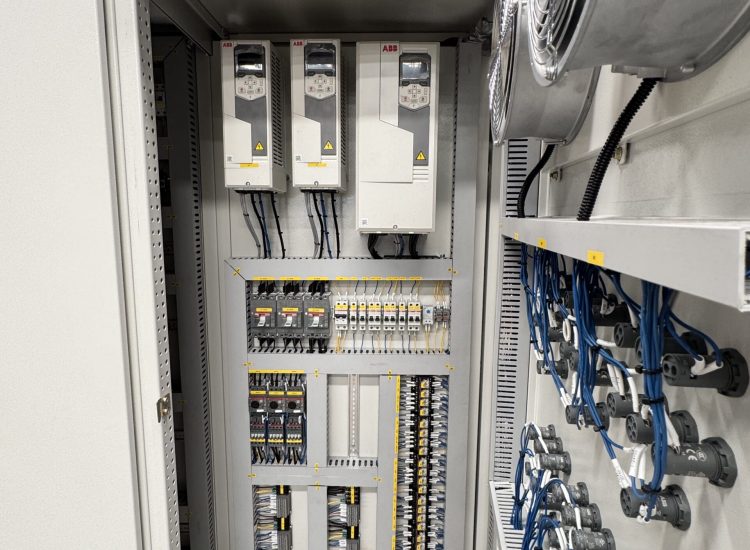

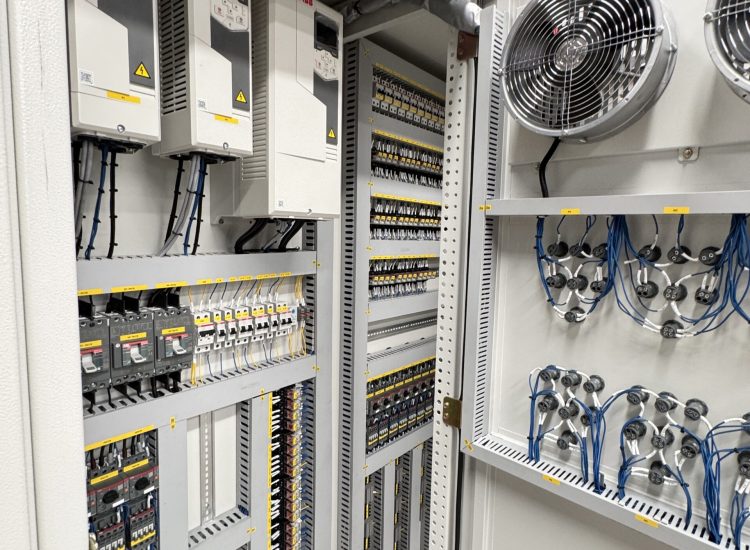

Clean, organized panel layout for easy maintenance and troubleshooting

Seamless integration with PLC and SCADA systems

Reduced downtime through clear diagnostics and alarm handling

Scalable design to support future plant expansion

- The earth is a planet of immense beauty

- Sun is an incredible source of energy

- Produce energy to generate electricity

Technologies What We Used

Industrial Control Panels (MCC / Control Panels)

PLC-Based Control Systems

Motor Control (Direct-On-Line, Soft Starter, VFD)

Power Distribution and Protection Devices

Instrumentation Signal Interfaces

Industrial Communication Networks

SCADA System Integration

Tablet-Based Smart Start-Up Control

This system demonstrates a tablet-based start-up process integrated with the plant’s PLC and SCADA architecture. Operators can initiate, monitor, and control the production process directly from an iPad, providing fast, intuitive, and flexible operation at the production floor.

The interface is designed for real-world industrial use, allowing operators to start sequences, verify interlocks, and confirm process readiness before full operation. Real-time feedback from sensors and machines is displayed instantly, ensuring safe start-up conditions and reducing the risk of human error.

By combining mobile control with Smart SCADA technology, this solution improves operational efficiency, shortens response time, and enhances overall plant visibility—supporting modern, digitalized production environments.