Benefits of Project

Smart SCADA helps industrial plants improve operational efficiency, system reliability, and production visibility. By integrating PLC systems, sensors, and industrial networks, Smart SCADA enables operators to monitor processes in real time and respond quickly to abnormal conditions.

With Smart SCADA, production data is collected, logged, and analyzed to support better decision-making. This reduces downtime, improves maintenance planning, and increases overall plant performance.

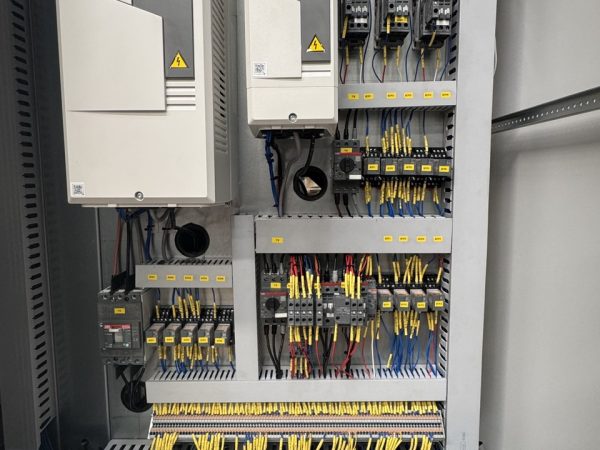

KRS ICS designs Smart SCADA solutions tailored to each production process, including electrical control systems, industrial automation, and real-time monitoring dashboards. Our systems are built for long-term stability, scalability, and easy integration with existing equipment.

Complete modernization of the control and monitoring system

Full automation of all production processes from start to finish

Improved process stability through AI-based PID auto-tuning

Reduced operator dependency and human error

Real-time visibility of production, alarms, and performance indicators

Scalable system architecture ready for future upgrades

Foundation for Smart Factory and digital transformation initiatives

- Complete modernization of the control and monitoring system

- Full automation of all production processes from start to finish

- Real-time visibility of production, alarms, and performance indicators

Technologies What We Used

PLC-based Automation System

SCADA System with Real-Time Visualization

Industrial Instrumentation & Sensors

AI-assisted PID Auto-Tuning Algorithms

Process Optimization & Data Analytics

Industrial Communication Networks (Fieldbus / Ethernet)

Alarm Management & Historical Data Logging