Benefits of Project

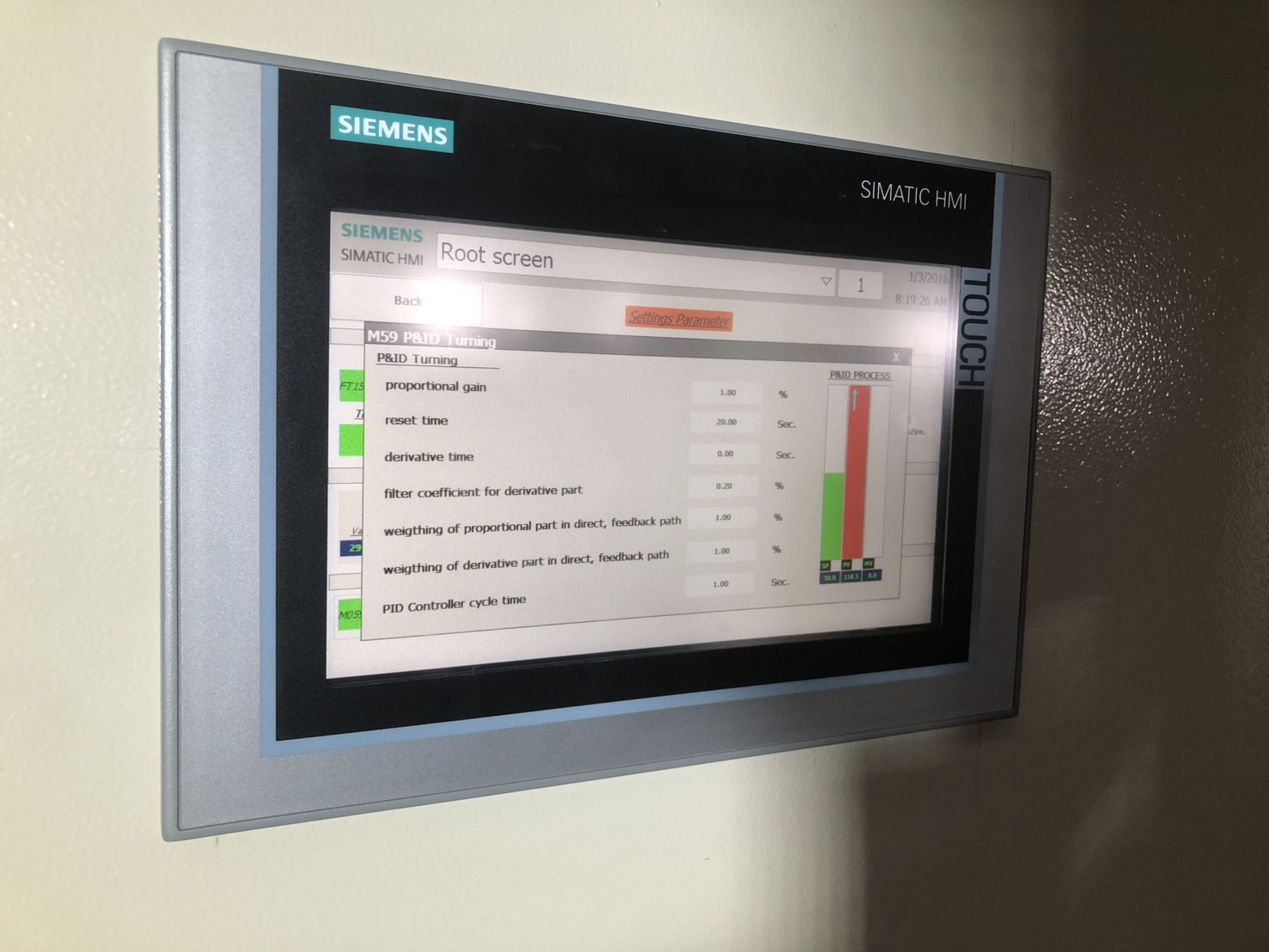

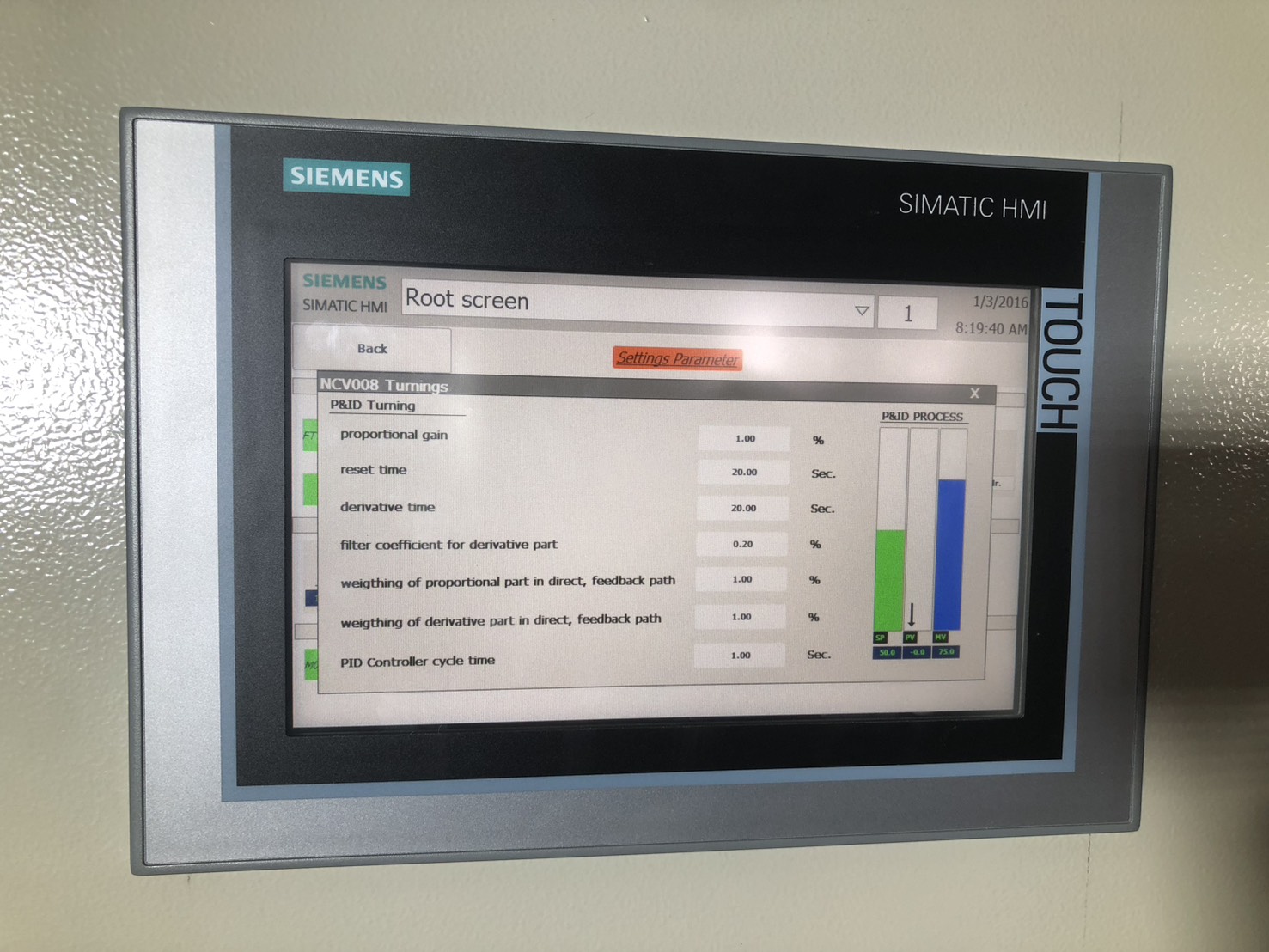

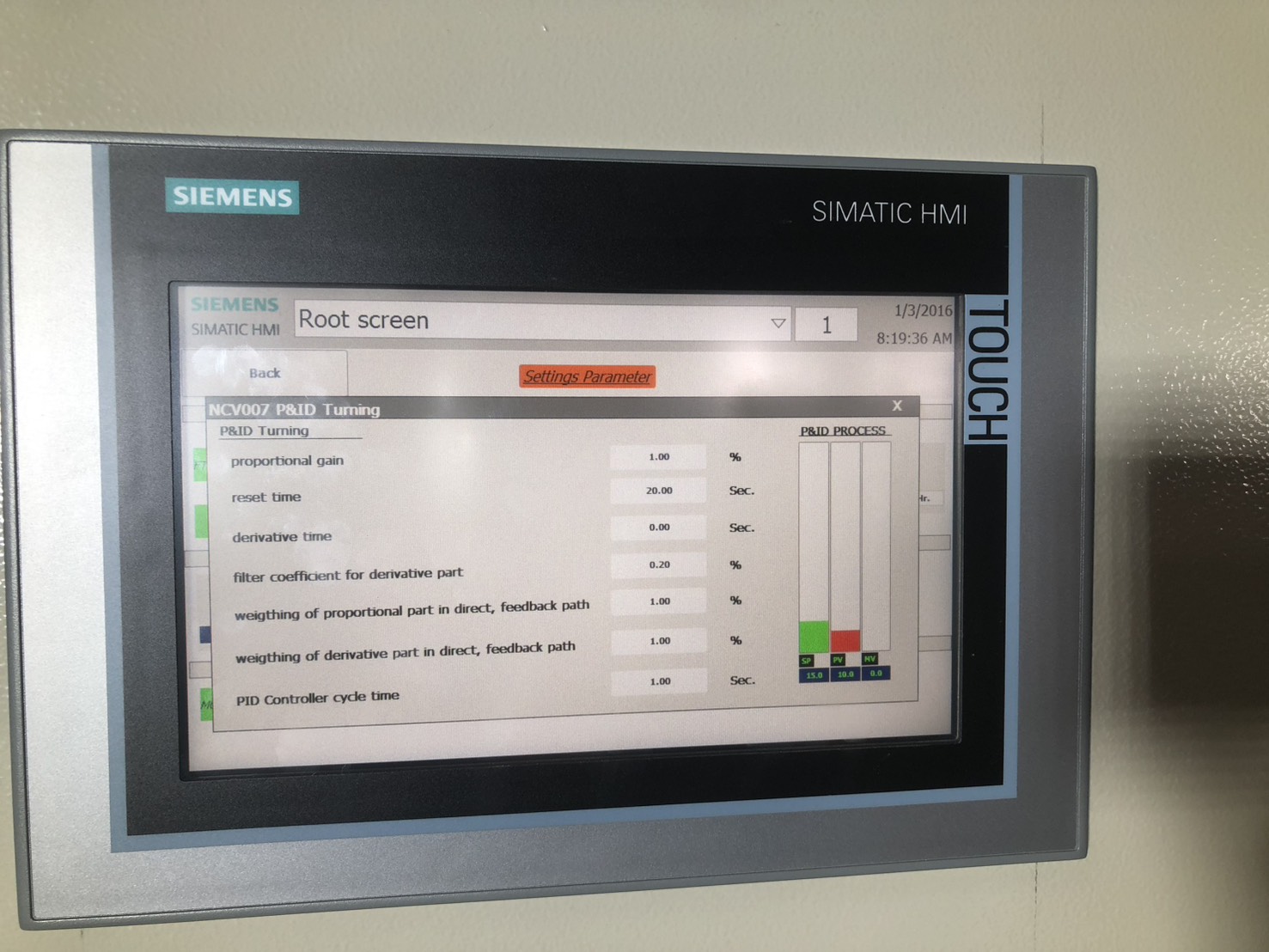

Stable and precise control of Hydro Cyclone operation

Improved separation efficiency and product quality

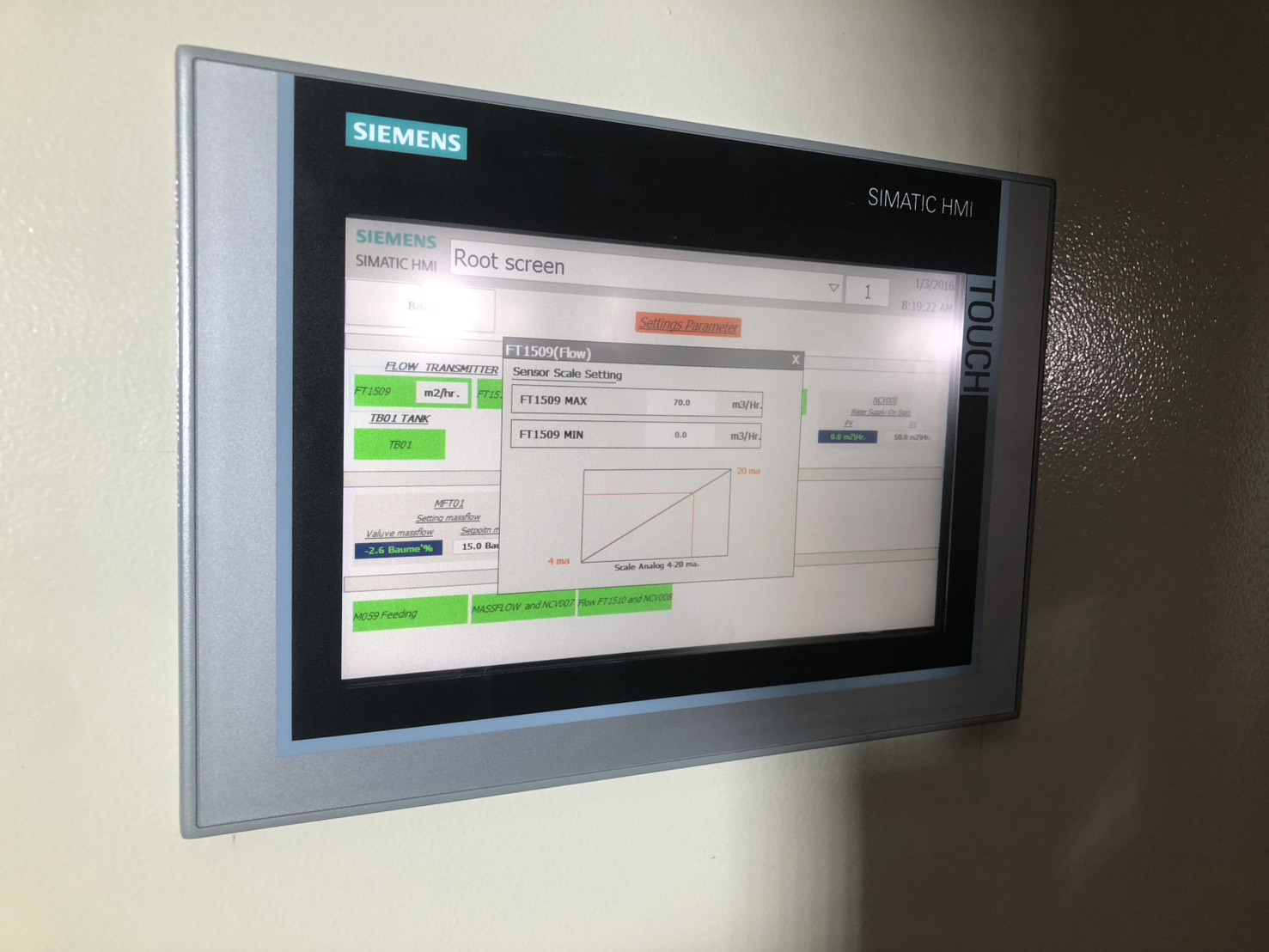

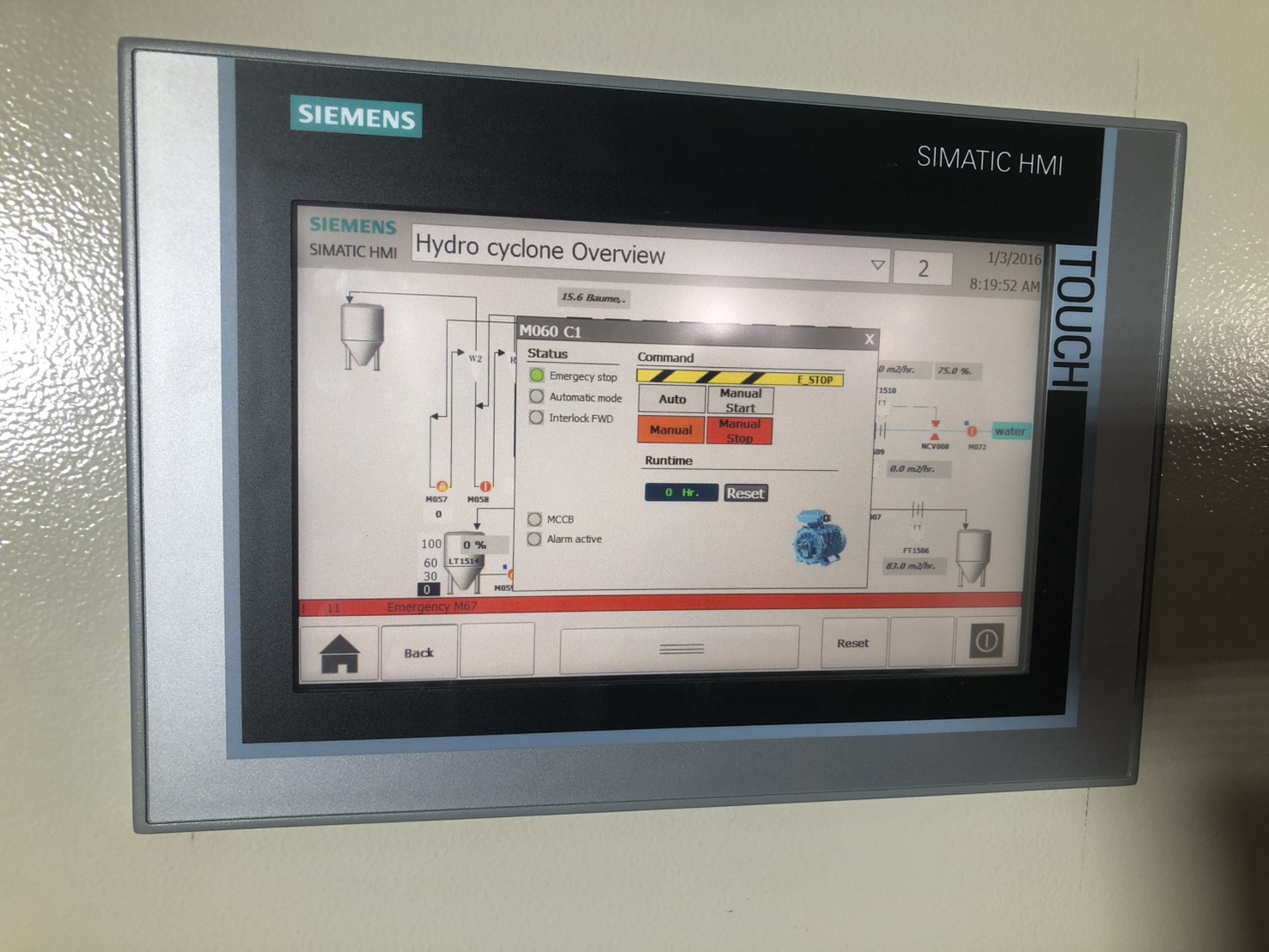

Real-time monitoring of critical process parameters

Reduced operator dependency through automated control logic

Faster troubleshooting with clear alarms and diagnostics

Increased system reliability and operational safety

Ready for integration into a plant-wide SCADA system

- Stable and precise control of Hydro Cyclone operation

- Stable and precise control of Hydro Cyclone operation

- Ready for integration into a plant-wide SCADA system

Technologies What We Used

PLC-based Control System (Siemens Platform)

SIMATIC HMI Touch Panel

Industrial Pressure & Flow Instrumentation

Automatic & Manual Control Logic

Alarm Management & Safety Interlocks

Modular Control Cabinet Design

SCADA-ready Communication Architecture