About the project

- Date: August 20, 2018

- Client: Envato Group, US

- Category: Energy

- Address: 2946 Angus Road, NY

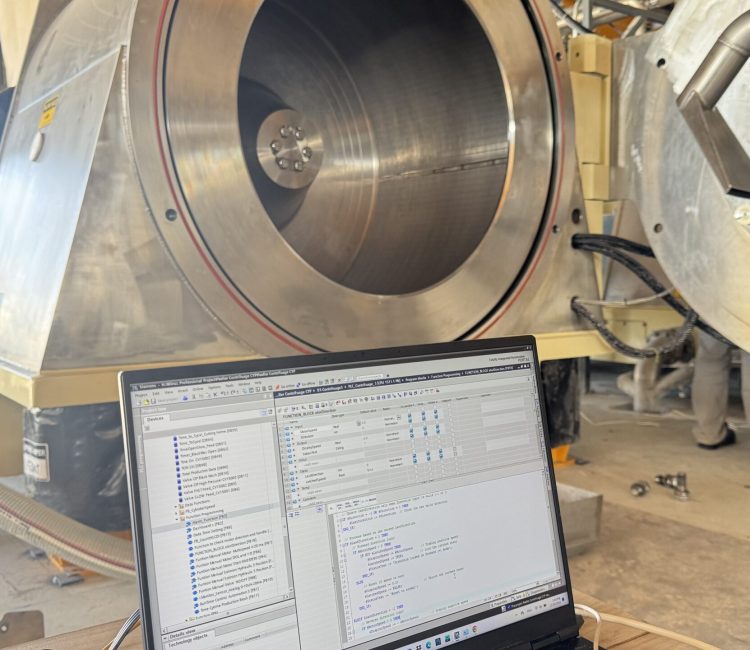

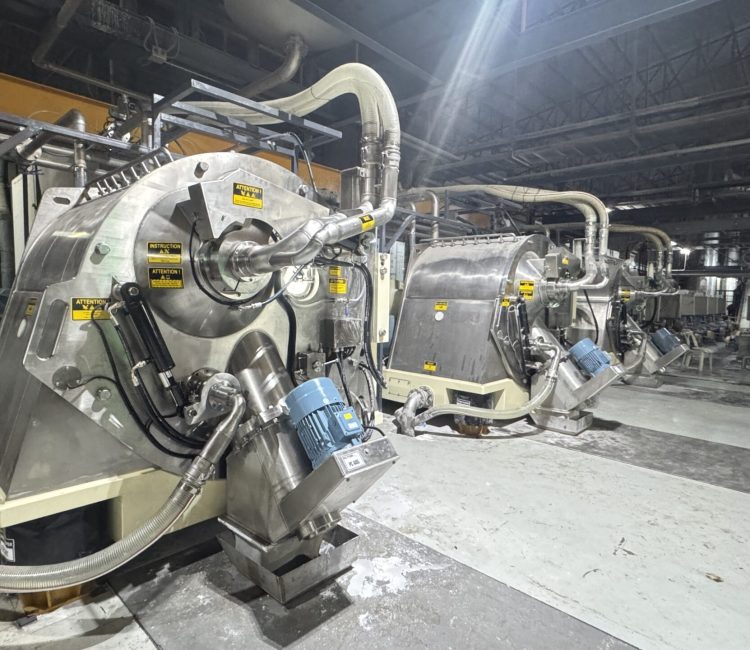

The Automatic Peeler Centrifuge Project was developed to fully automate the solid–liquid separation process in industrial production lines, replacing conventional manual and semi-automatic operation with a high-performance PLC and SCADA-based control system.

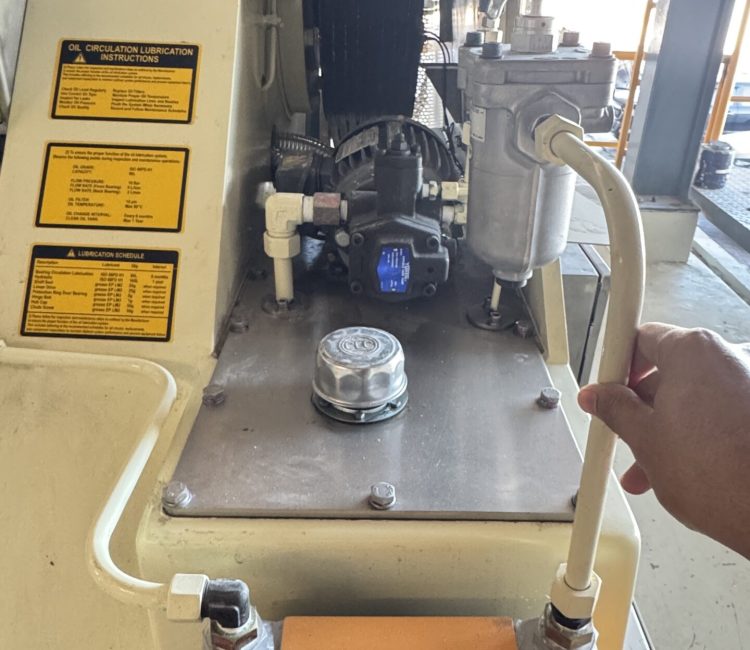

The project scope covered the complete integration of mechanical equipment, electrical systems, instrumentation, and automation control, ensuring stable, repeatable, and efficient centrifuge operation. All process sequences—including feeding, acceleration, separation, peeling, discharge, and cleaning—are executed automatically based on predefined logic and real-time process feedback.

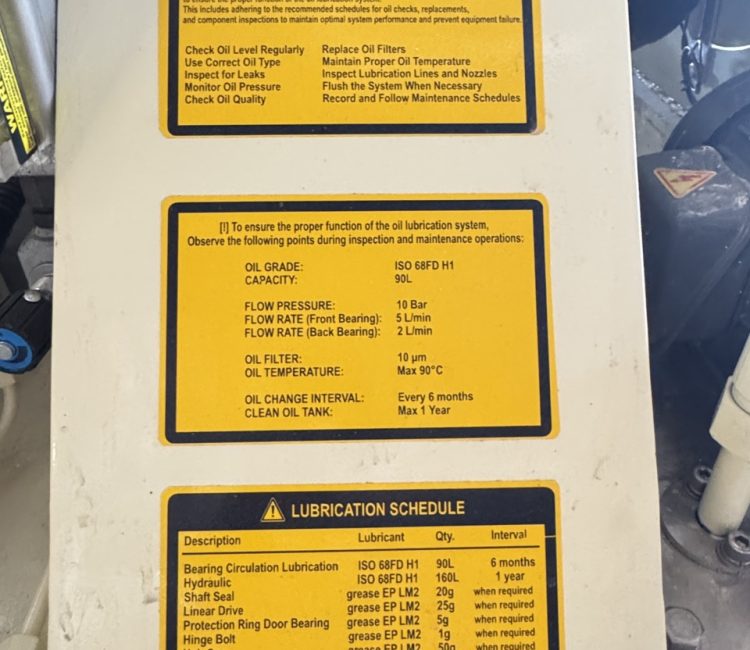

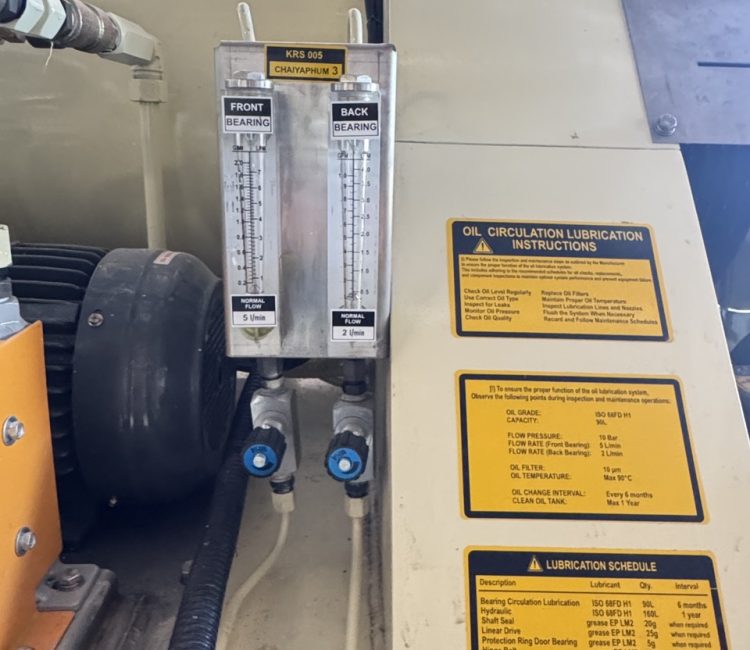

Industrial sensors were installed to continuously monitor critical parameters such as rotational speed, vibration, pressure, flow rate, torque, and motor load. These signals are processed by the PLC and visualized through the SCADA system, allowing operators to supervise the centrifuge in real time, adjust operating parameters, and respond quickly to abnormal conditions.

Advanced automation logic ensures precise control of cycle timing, peel knife operation, and discharge sequences, resulting in consistent product quality, reduced product loss, and improved overall throughput. The centralized control architecture also enables seamless integration with upstream and downstream processes within the production line.

This project demonstrates a modern approach to centrifuge automation, delivering improved reliability, reduced operator dependency, enhanced safety, and long-term operational stability.