Benefits of Project

Fully automated production process from start to finish

Improved production stability and operational reliability

Real-time monitoring and centralized control via SCADA

Higher product quality consistency

Reduced human error and manual intervention

Optimized energy and resource usage

Scalable system design for future expansion

Foundation for Smart Factory and Industry 4.0 implementation

- Fully automated production process from start to finish

- Improved production stability and operational reliability

- Real-time monitoring and centralized control via SCADA

Technologies What We Used

PLC-based Automation System

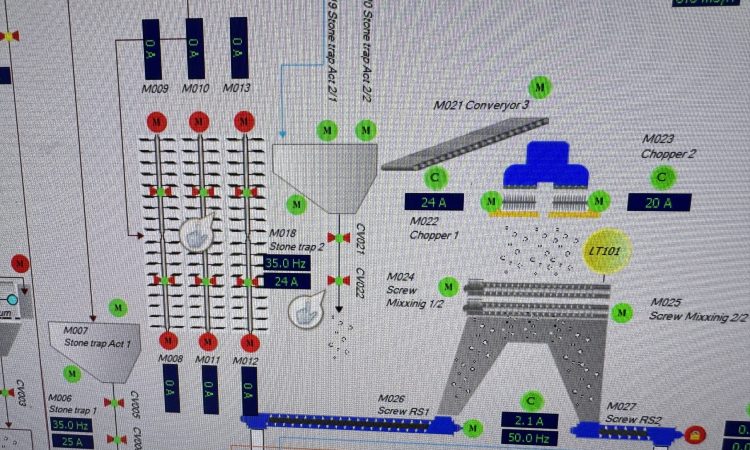

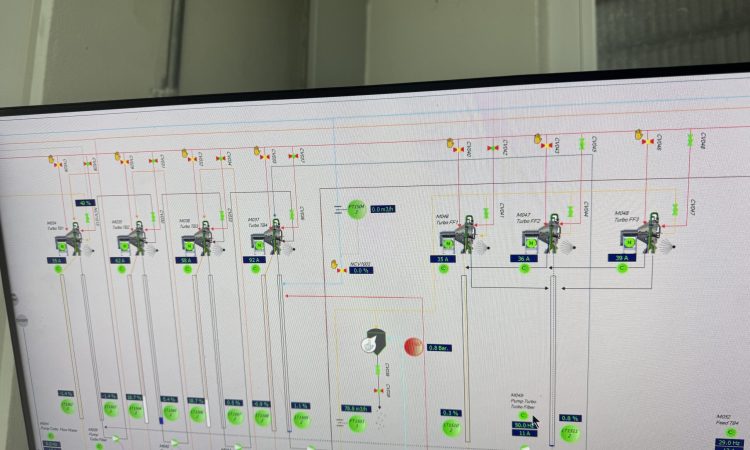

SCADA & HMI Visualization

Industrial Sensors & Instrumentation

Electrical Control Panels & MCC Systems

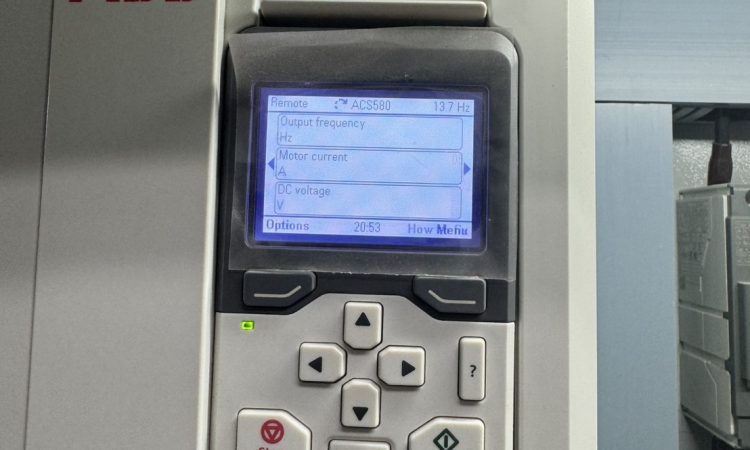

Variable Frequency Drives (VFD)

Industrial Network & Communication Systems

AI-assisted PID Tuning and Advanced Control Logic

Data Logging, Trending, and Alarm Management

Smart SCADA & AI-Driven Plant Automation

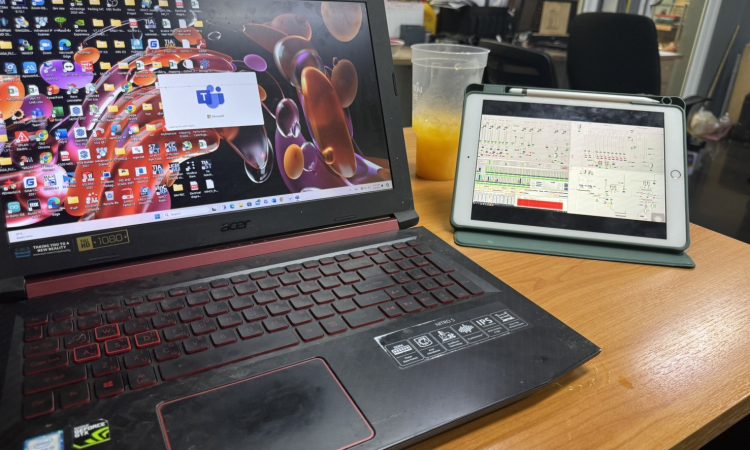

We deliver complete end-to-end industrial automation solutions, covering the entire production process from the first operation to the final output. Our scope includes mechanical integration, electrical systems, instrumentation, PLC programming, and full SCADA implementation, all designed as one unified and intelligent control system.

This project was developed to replace the legacy control system entirely. We redesigned the process logic, installed new industrial-grade sensors, and implemented a centralized PLC–SCADA architecture to ensure stable, reliable, and real-time plant operation. Every stage of production is monitored, controlled, and optimized through a single Smart SCADA platform.

To further enhance performance, we integrated AI-assisted control algorithms into the system, enabling advanced PID auto-tuning and adaptive process control. The AI continuously analyzes real-time process data, automatically adjusts control parameters, and responds to changing operating conditions without human intervention. This results in higher production efficiency, improved product consistency, reduced energy consumption, and minimized downtime.

Our Smart SCADA solution transforms traditional manufacturing plants into next-generation intelligent factories, where data-driven automation, predictive control, and real-time visualization work together to support modern industrial operations and long-term sustainability.

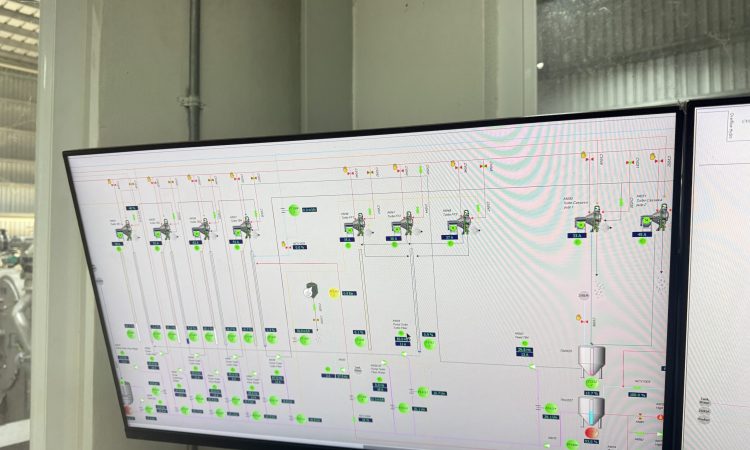

Real-Time SCADA Visualization & Intelligent Monitoring

This SCADA system provides real-time visualization and monitoring of the entire production process through an intuitive and operator-friendly interface. All critical parameters such as flow, pressure, level, motor status, energy consumption, and alarms are displayed clearly, enabling operators and engineers to make fast and accurate decisions.

The system is designed to support centralized control, data trending, alarm management, and historical data logging, ensuring full transparency of plant operations. Integrated dashboards allow users to track performance, identify deviations, and respond to process abnormalities before they impact production.

By combining SCADA visualization with AI-enhanced analytics, the platform not only shows current operating conditions but also supports process optimization, fault prevention, and continuous improvement. This intelligent monitoring layer is a key component of our Smart SCADA architecture, bridging operational data with advanced automation and digital manufacturing strategies.